Our Training Process

Before working with studio equipment, we require a Safety and Basic Use (SBU) class. As the name suggests, SBUs are introductory learning experiences on the safe handling and essential functions of specific tools.

Our SBUs are divided into two portions: an asynchronous online module that is completed first and then an in-person training session (approx. 45 min) that includes hands-on practice with the specific machine.

-

1

Getting Started

To access the SBUs, you'll need to enroll in our Hello Maker Studio Canvas. Next, complete the Culture & Mission module and short quiz. Passing the quiz will unlock all of the available online SBUs which you may complete at your own pace.

-

2

Online SBU Module

See below for the specific equipment that can be accessed in the studio; each one has its own SBU. Complete the module at your own pace and complete the quiz that accompanies it.

-

3

In-Person Training

Upon completion of the online module, click on the Calendar icon on the main Canvas menu. Click on the "Find Appointments" button on the right, then select "Hello Maker Studio" on the drop down menu. This will display all of our available training classes and all you'll need to do is select the day and time that works best for you.

Skill Building

Besides our formal SBUs, the Hello Maker Canvas also offers several asynchronous Skill Building modules covering a wide range of topics from cardboard construction techniques to programming electronics with Arduino.

On Demand Training

Not every tool in the studio requires an SBU, however. We offer a variety of basic hand and craft tools that can be learned in just a few minutes with guidance from our studio staff.

Texas Invention Works (TIW)

For those who have Bambu Labs 3D Printer training at TIW, Hello Maker Studio will waive the SBU requirement for our PS1 printers. Simply present proof that the training was completed.

Studio Equipment

Digital Fabrication

Our digital fabrication tools let you turn ideas on a computer into real, physical objects using machines like 3D printers and laser cutters. You can create a digital design, send it to the machine, and it automatically builds or cuts your design from materials like plastic, wood, or metal.

3D Printing

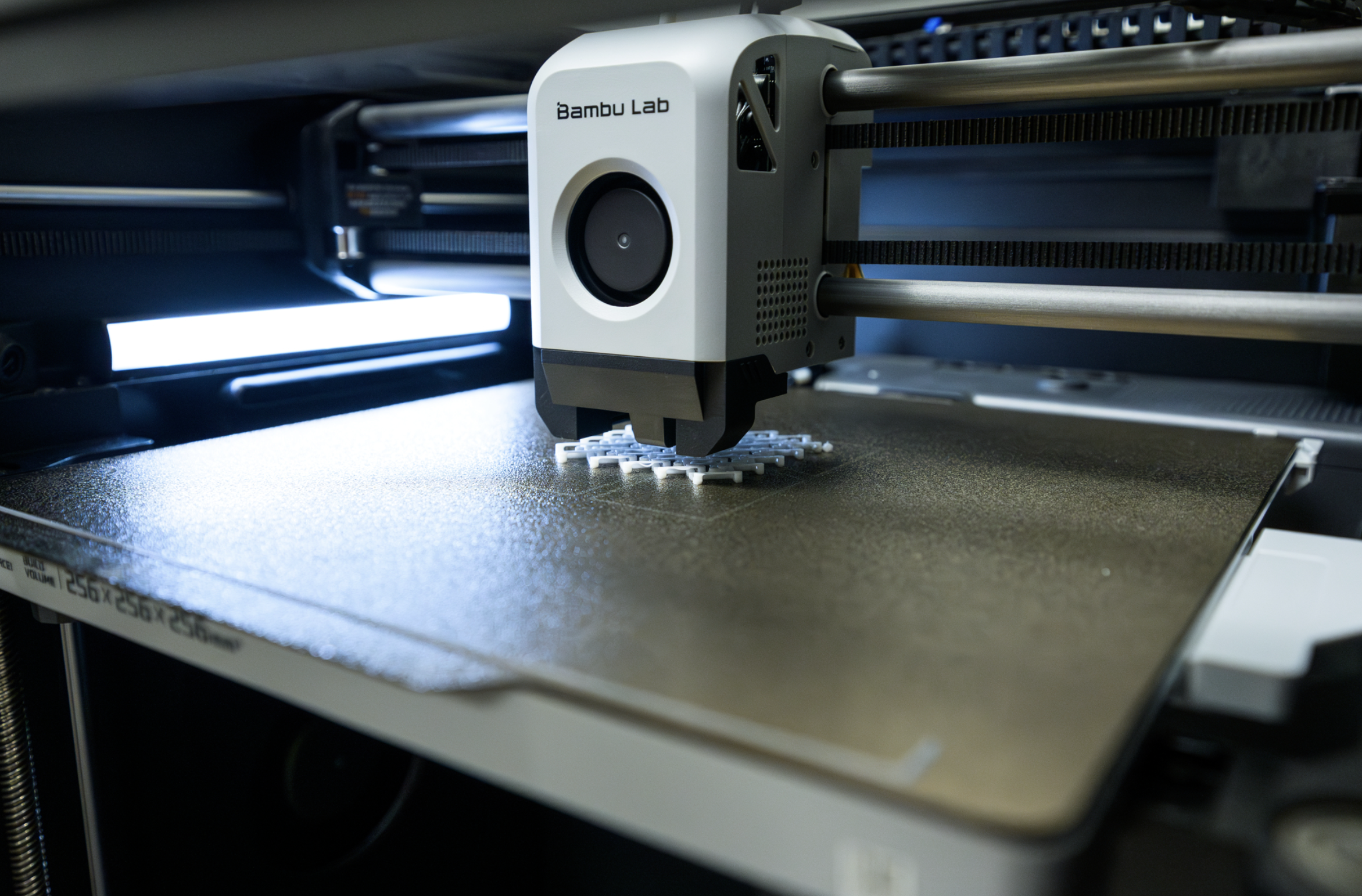

Bambu P1S/AMS

3D printing is a process that allows the user to create a 3D object by stacking thin consecutive layers of heated plastic. Bambu printers are both quick and accurate, making them an excellent choice for beginners and experts alike.

Laser Cutting

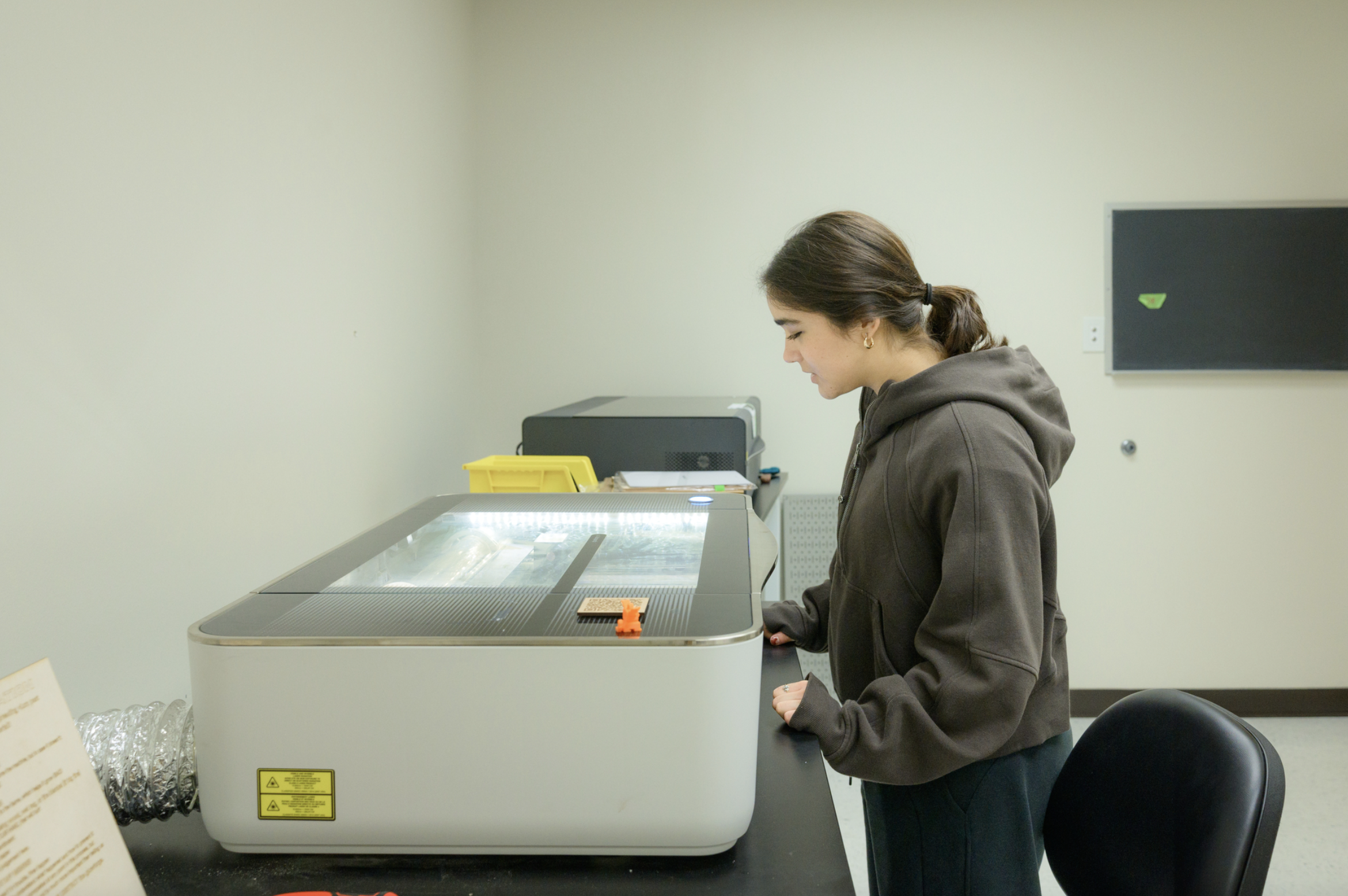

Glowforge Pro (45-watt, CO2)

Laser cutting uses an extremely thin, powerful and invisible laser beam to burn away material. An ideal for desktop laser cutter beginners. There's no software to download and it can cut, score and engrave on a variety of materials including wood, acrylic, leather and textiles.

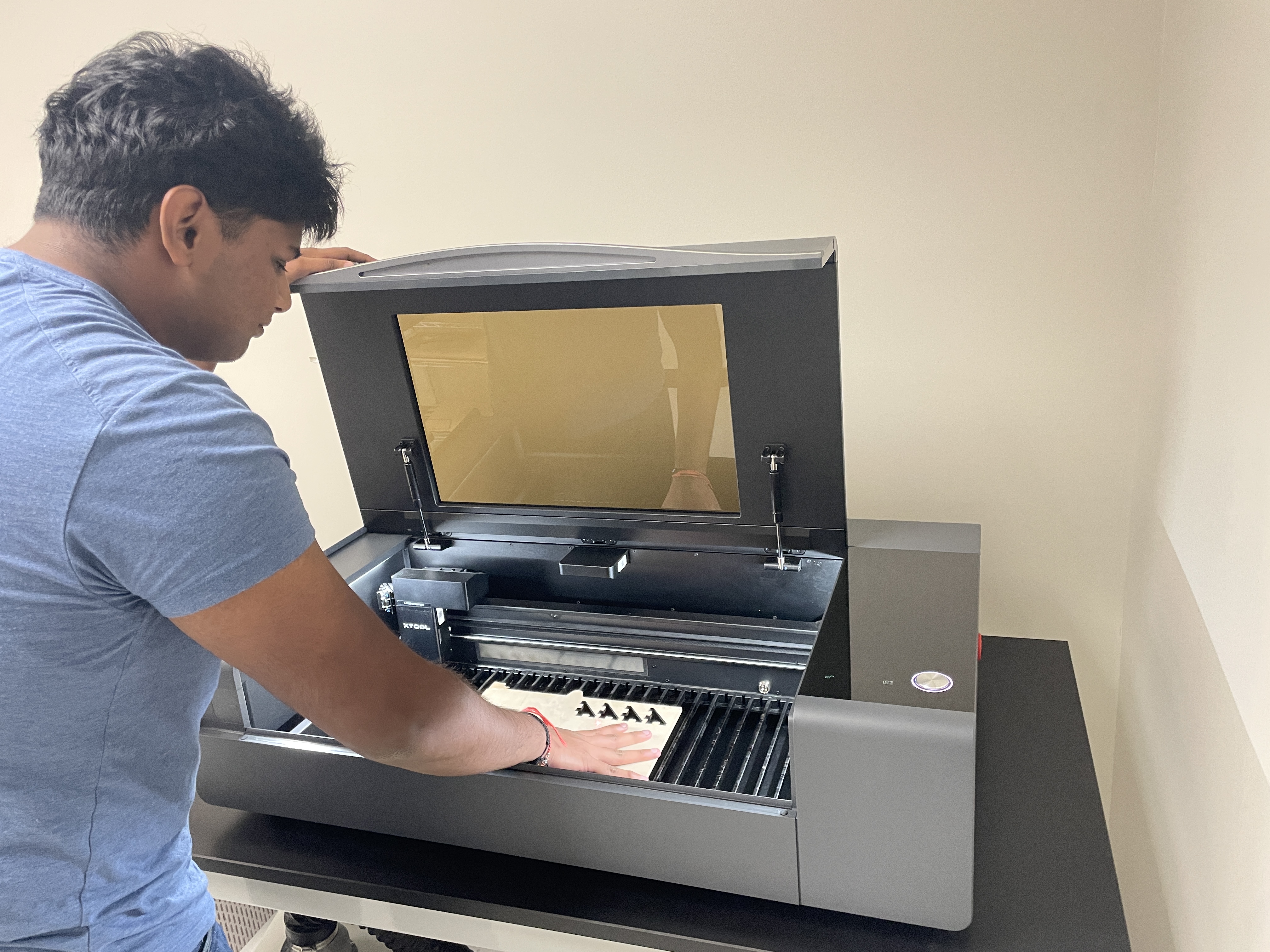

xTool P2S (55-watt, CO2)

Similar to the Glowforge, this desktop laser has a larger cutting area, free software and specialized equipment for screen printing.

Vinyl Cutting

Cricut Maker 3

Instead of lasers, the Cricut has a variety of interchangeable blades that do the cutting. This is the perfect machine for making stickers, decals, iron-on shirt design and paper crafting.

CNC Milling

Carvera CNC

This desktop mill is essentially a 3D carving machine that uses specialized "drill bits" called end mills to drill, shape and etch wood, plastic, printed circuit boards (PCBs) and even metal.

Electronics

Our electronics area provides everything you need to build interactive projects using microcontrollers like Arduino and micro:bit, which can control lights, motors and sensors to respond to the world around them. With breadboards for prototyping ideas and soldering stations for permanent builds, you can create everything from simple blinking lights to complex robots that sense motion, temperature, or sound.

Analog Fabrication and Textiles

Analog fabrication means making things by hand, using traditional tools and techniques instead of digital files or automated machines. Our studio offers training and access to hand tools, power equipment, sewing machines and cutting tools for working with a variety of materials.